Nissan K24 Propane Pressure Sensor

The Nissan K24 propane pressure sensor is integral to the operation of propane-fueled vehicles. It ensures that the vehicle runs smoothly by accurately monitoring and regulating fuel pressure. In this article, we will explore the sensor’s role, the benefits it provides, how it operates, and essential maintenance tips to keep it functioning correctly. By the end, you’ll understand why this sensor is critical to your vehicle’s performance and how to maintain it effectively.

What is the Nissan K24 Propane Pressure Sensor?

The Nissan K24 propane pressure sensor’s is a vital component in vehicles that use propane as a fuel source. It measures the pressure of the propane gas within the fuel system and transmits this data to the engine control unit (ECU). Consequently, this information allows the ECU to adjust the fuel mixture and engine settings to ensure optimal performance and safety.

Key Functions:

- Pressure Measurement: The primary function of the sensor is to measure the pressure of propane gas. This ensures that the engine receives the correct amount of fuel.

- Data Transmission: The sensor sends real-time pressure data to the ECU. This allows the ECU to make precise adjustments to the fuel mixture and other engine parameters.

- Safety Monitoring: By monitoring the pressure, the sensor helps prevent issues such as pressure imbalances that could lead to engine damage or unsafe driving conditions.

Importance of the Nissan K24 Propane Pressure Sensor

The K24 propane pressure sensor plays a crucial role in maintaining vehicle efficiency and safety. Here’s why:

- Optimized Engine Performance: Accurate pressure measurement ensures that the ECU can adjust the fuel mixture for optimal engine performance. As a result, drivers experience smoother acceleration and overall better vehicle responsiveness.

- Enhanced Fuel Efficiency Proper pressure regulation leads to efficient fuel combustion. This improved efficiency translates into better fuel economy, which is essential for reducing operational costs, especially for fleet operators who rely on propane-powered vehicles.

- Reduced Emissions: Accurate pressure management helps in complete combustion of propane. This reduction in incomplete combustion lowers the emission of harmful pollutants, aiding in compliance with environmental regulations.

- Prevention of Engine Damage: Consistent monitoring of propane pressure prevents issues such as overpressure or under pressure that could cause significant engine damage. Regular and accurate pressure readings ensure that the engine operates within safe parameters.

How the Nissan K24 Propane Pressure Sensor Works

Components and Mechanism:

- Pressure Transducer: At the core of the sensor is a pressure transducer. This device converts the physical pressure of the propane gas into an electrical signal.

- Signal Transmission: The electrical signal generated by the pressure transducer is transmitted to the ECU. The ECU processes this information to make necessary adjustments to the engine‘s fuel mixture and operational parameters.

- Calibration: For accurate readings, the sensor must be calibrated regularly. Proper calibration ensures that the sensor provides precise pressure measurements, which are critical for optimal engine performance.

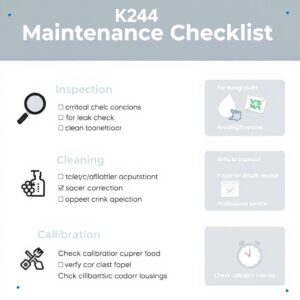

Maintenance Tips for the Nissan k24 Propane Pressure Sensor

To ensure the Nissan K24 propane pressure sensor remains in optimal condition, follow these maintenance tips:

- Regular Inspections: Periodically inspect the sensor for any signs of wear or damage. Look for issues such as leaks or corrosion that could affect the sensor’s performance. Regular inspections help catch problems early, preventing more significant issues.

- Clean Connections: Electrical connections to the sensor should be kept clean. Debris or corrosion on these connections can interfere with the signal transmission. Cleaning these connections regularly can prevent performance issues.

- Check Calibration: Calibration of the sensor should be performed at regular intervals. Accurate calibration is essential to avoid discrepancies in pressure readings, which can affect engine performance and emissions.

- Replace When Necessary: If the sensor starts malfunctioning or providing inaccurate readings, it should be replaced promptly. Replacing a faulty sensor is crucial for maintaining engine performance and safety.

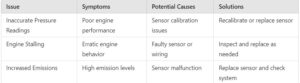

Troubleshooting Common Issues

Here’s a table outlining common issues with the Nissan K24 propane pressure sensor, their symptoms, and solutions:

Conclusion

In summary, the Nissan K24 propane pressure sensor is essential for vehicles running on propane. It ensures accurate monitoring and regulation of fuel pressure, which is critical for engine performance, fuel efficiency, and emission control. Regular maintenance and timely replacements are crucial to keep the sensor functioning effectively. By understanding the sensor’s importance, vehicle owners and fleet operators can make informed decisions to maintain their vehicles in optimal condition.

FAQs

1. What happens if the Nissan K24 pressure sensor fails?

If the sensor fails, it can lead to poor engine performance, increased emissions, and potential engine damage. Symptoms include erratic behavior, stalling, or inaccurate pressure readings.

2. How often should I replace the pressure sensor?

Replace the sensor if it malfunctions or shows inaccurate readings. Regular inspections and calibration can help identify issues early.

3. Can I clean the propane pressure sensor myself?

While you can clean the sensor’s connections, it’s best to have a professional inspect and service the sensor to ensure it is functioning correctly.

4. How do I calibrate the Nissan K24 propane pressure sensor?

Calibration should be performed by a professional mechanic or technician using the proper tools to adjust the sensor accurately